BQS Machine Manufacturer - Jochamp

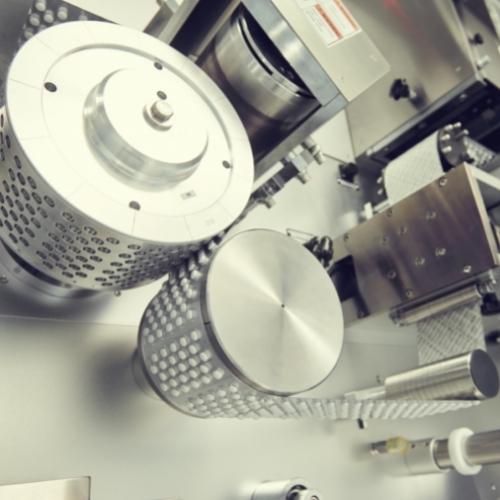

Jochamp BQS Machine is equipped with a modern servo that improves precision blister packing. It offers high capacity and quality for your manufacturing process. It is thoroughly manufactured from high-quality steel and the parts are sourced from internationally renowned brands.

- Easy to operate and long-lasting

- Cost-effective packaging solution

- Customized design to suit your needs

- Serves medical and pharmaceutical industry

JOCHAMP BQS Machine

Jochamp manufactures BQS machine or blistering quickly through servo machine for your needs. It works using an advanced servo technology allows for efficient flat-sealing, flat-forming, and continuous motion blister packing operation. The purpose of this system is to detect any non-filled blisters. It offers high-speed, high-accuracy and easy production of your products.

Jochamp provides various models and types of BQS machine. We can also support custom-built machines with strong construction and modular design. For more than 15 years we focused on the R&D and manufacturing of packaging machinery. You can trust our process 100%.

Message us immediately.

JCDH-260 Blistering Quickly through Servo Blister Packing Machine

This blister packaging machine is suitable for automatic high-speed ALU-PVC packing of capsules, tablets and other regular shape medicine. It adopts flat pressure forming to form strong and average blisters, and roller type mesh sealing to ensure reliable sealing. The machine is equipped with batching system, embossing device and horizontal boundless punching to achieve high automation and efficiency.

- Fast mould change, push-oriented, without using tools

- Adopt servo traction, simple to set up, convenient to debug

- Push-oriented punch mould installation. If inspection and reject system is equipped and changed, no need to dismantle suck discs

- Long distance between two heating plates of forming when machine stops, to avoid PVC to be excessively heated and softened.

- Optional configurations include camera inspection and rejection device, mechanical hand structure with suck heads, automatic vibrating guide rail feeder, etc.

JCDH-260

- Technical Parameter

- Features

- Optional

| Item | Unit | Specification | |||||

| Blanking Speed Standard Card (80mm×57mm)×4 Row | Cycle / min | 100-150 | |||||

| Capacity | Cards / hour | 360Pcs/min | |||||

| Range of stroke | mm | 40-120 | |||||

| Max. forming area and depth | mm | 240×260×12 | |||||

| Power supply | V | Hz | Kw | AC380/220 | 50/60 | 10 | |

| Air consumption | Stere / min | ≥0.5 | |||||

| Packing Material | Pharmacy PVC | mm | 0.25×260 | ||||

| PTP Aluminum foil | mm | 0.02×260 | |||||

| Overall dimension (Length×Width×High) | mm | 4220×1020×1020 | |||||

| Packaging Dimension(Length×Width×High) | mm | 4600×1250×1960 | |||||

| Net weight | Kg | 3000 | |||||

Fast mould change, push-oriented, without using tools

Adopt servo traction, simple to set up, convenient to debug

Push-oriented punch mould installation. If inspection and reject system is equipped and changed, no need to dismantle suck discs

Long distance between two heating plates of forming when machine stops, to avoid PVC to be excessively heated and softened.

Optional configurations include camera inspection and rejection device, mechanical hand structure with suck heads, automatic vibrating guide rail feeder, etc.

visual inspection

Batch number stamping

Rotary suction head discharge

Laser positioning function

Remote system inspection, maintenance, upgrade

Sealing pattern

Punching mechanism

Jochamp BQS Machine Features and Advantages

- High production for both PVC and PVDC

- Alu/Alu (280 blisters/minute) or customized

- PVC/PVdC (600 blisters/minute) or customized

- Provide simple operation and fast changeover

- High-speed continuous motion flat forming and flat sealing equipment.

- Consistent and unique drum feeding systems

- Tool-free switching between PVC/Alu and Alu/Alu.

- Provide precision power, speed, and position control via servo.

BQS Machine Product Scope

Blister Packing Equipment BQS is a continuous motion flat-bed compressed air forming and flat sealing machine for blister packaging of the following:

- Tablets

- Capsules

- Hard gelatin capsules

- Soft gelatin capsules, etc.

This machine handles PVDC/PVC, and ALU base films. It is a functional and high-performance machine for the pharmaceutical industry.