Blister Cartoning Machine Manufacturer in China

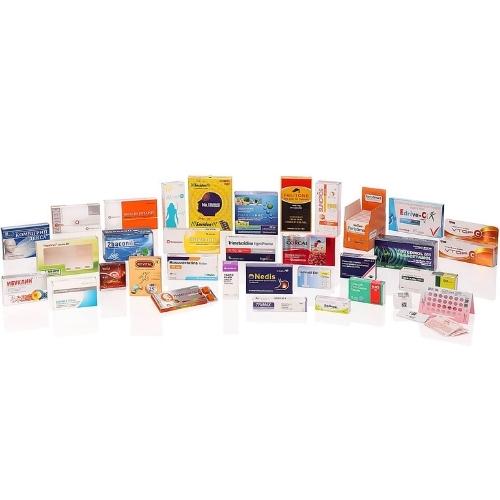

JOCHAMP is a one-stop solution for blister cartoning machine needs in China. We supply superior quality machines suitable for packing pharmaceutical, nutraceutical, cosmetics products, etc.

- Easy to operate

- Low noise operation

- Maximum speed reaches 650ppm

- Simple and powerful industrial control system

JOCHAMP Blister Cartoning Machine

Blister cartoning machine is an automatic/semi-automatic machine used in the packaging of capsules, biotechnology products, health, and nutritional supplements, natural food, etc. It packs tablets and capsules among products in blister packages before a secondary carton package. The structure of this machine is made from top-grade stainless steel material. It exhibits corrosion-resistant and durable features.

Our company can produce blister cartoning machines with a standard speed of 80 cartons per minute, 100 cartons per minute, 380 cartons per minute, or even customized. This machine is equipped with a smart detecting system, PLC, and touch-screen control. It is easy to operate, has convenient maintenance, and maintains the integrity of the product.

For your specifications, please contact us immediately!

Types of Blister Cartoning Machines

The entry-level blister cartoning machine is a user-friendly and versatile packaging equipment, offering a speed range of 10-60 boxes per minute. Its design allows for easy disassembly, making it convenient for setup, maintenance, and cleaning.

This cost-effective machine is an excellent choice for small businesses and start-ups looking to optimize their packaging processes. With its moderate speed and simple operation, it efficiently packages products into cartons, enhancing productivity while maintaining product quality.

The entry-level blister cartoning machine’s flexibility and affordability make it a valuable asset for small businesses seeking to improve their packaging capabilities and compete effectively in the market. Its reliable performance and ease of use make it the ideal entry point into automated packaging for those new to the industry.

The advanced Blister Cartoning Machine is a perfect choice for small businesses seeking to enhance their packaging capabilities. This high-tech machine offers a remarkable speed of up to 120 products per minute (PPM), significantly increasing packaging efficiency.

Equipped with extended functions, this advanced machine can handle various packaging tasks, such as blister packaging and cartoning, in a single streamlined process. Its versatility allows it to package different product types and sizes with ease.

With faster operation and automation, the advanced Blister Cartoning Machine reduces manual labor, minimizes errors, and optimizes production output, making it a cost-effective investment for small businesses.

This cutting-edge machine empowers small businesses to compete effectively in the market, offering efficient and reliable packaging solutions that meet industry demands while maintaining product quality and visual appeal. Its advanced features and speed elevate packaging capabilities, positioning small businesses for growth and success in the competitive landscape.

The enlarged Blister Cartoning Machine is specially designed for efficiently loading multiple blisters into one carton or for collective packaging of multiple cartons. With its advanced capabilities, this machine streamlines the packaging process and optimizes productivity.

For products that require multiple blisters to be packed together, such as multipacks or variety packs, the machine seamlessly handles the task. It precisely loads and arranges the blisters into the cartons, ensuring a neat and secure packaging presentation.

Moreover, the machine facilitates collective packaging, allowing multiple cartons to be grouped together for bulk packaging or promotional purposes. This feature enhances product handling and distribution efficiency, reducing the need for manual assembly.

The enlarged Blister Cartoning Machine is an invaluable asset for businesses seeking to maximize packaging versatility and improve overall packaging performance. Its ability to handle various packaging configurations makes it ideal for diverse industries, from pharmaceuticals to consumer goods, empowering them to meet customer demands with precision and flexibility.

The semi-automatic Blister Cartoner stands out for its user-friendly design and straightforward operation. Its manual loading feature makes it easy to use, requiring minimal training for operators. This simplicity makes it a suitable option for businesses of all sizes and industries.

With its semi-automatic functionality, the machine efficiently handles blister packaging tasks while still allowing operators to have control over the loading process. This flexibility is beneficial for businesses with various product types and packaging requirements.

The semi-automatic Blister Cartoner offers a cost-effective solution, enabling businesses to improve their packaging capabilities without the need for full automation. Its ease of use and versatility make it an attractive choice for those seeking to enhance packaging efficiency and presentation.

This reliable and accessible machine empowers businesses of all types to achieve professional blister packaging results while maintaining operational simplicity and cost-effectiveness.

The continuous Blister Cartoning Machine is a high-performance packaging equipment, offering smooth and efficient operation. With an impressive speed of up to 300 products per minute (PPM), this machine is specifically designed to meet the demanding needs of large enterprises.

Its continuous operation ensures a seamless and uninterrupted packaging process, maximizing productivity and minimizing downtime. This fast and reliable machine significantly improves packaging efficiency, making it an ideal choice for large-scale production.

The continuous Blister Cartoning Machine’s advanced capabilities and high-speed operation make it a valuable asset for large enterprises seeking to optimize their packaging processes. Its ability to handle large volumes of products with precision and consistency ensures a cost-effective and competitive packaging solution.

This cutting-edge machine empowers large enterprises to meet market demands effectively, streamline production, and deliver neatly packaged products at an impressive speed, maintaining product quality and enhancing the overall competitiveness in the industry.

The top-loading Blister Cartoning Machine is an ideal choice for efficiently packing scattered products. Its unique operation mode allows for easy loading of products from the top, making it highly suitable for handling products that are not aligned in a single row.

With this specialized feature, the machine can effectively accommodate products of different shapes and sizes, even if they are not arranged in a uniform manner. This flexibility makes it a versatile solution for various industries, from pharmaceuticals to consumer goods.

The convenient operation of the top-loading Blister Cartoning Machine ensures ease of use for operators. Its user-friendly design minimizes manual intervention and reduces the risk of errors, resulting in improved packaging efficiency and productivity.

This innovative machine streamlines the packaging process for scattered products, enhancing product presentation and protection. It is a valuable asset for businesses seeking to optimize their packaging operations while maintaining the quality and consistency of their products.

Blister Cartoning Machine Feature

Blister cartoning machines offer high cartoning speeds. It can work at an advanced speed of 100 cartons/380 cartons in a minute.

The tooling system is easy to control to pack various sizes of blister cartons. It can pack individual blisters or multiple blisters.

Our series of blister cartoning machines are designed with compact and ergonomic designs to increase stability and safety.

You can guarantee the machine’s compliance with the set industry standards and norms such as CE, SGS, ISO, and cGMP certification.

Benefits of Using Blister Cartoning Machine

Several advantages you can enjoy utilizing Jochamp Blister Cartoning Machine.

- Ease of identifications

- Maintains dose accuracy

- Sustains product’s integrity

- Blister carton exhibits tamper proof properties

- Cost-effective packaging

- Flexibility and ease of operations

- Low maintenance

- Assemble from high-quality component

- High speed of 80/100/380 cartons per minute

Industries Use Blister Cartoning Machine

Due to their high-performance, easy to operate, high-quality parts, and durable construction, these machines are sold in the market. They are used in various industries such as:

- Nutraceutical Industry

- Pharmaceutical Industry

- Chemical Industry

- Cosmetics Industry

- Food Processing Industry to package biscuits and pastries, etc.

Blister Cartoning Machine Parts

Using high-grade components, Blister cartoning machine will work well and be long-lasting. Every part is well-manufactured, tested, and inspected to the highest quality standards, it includes:

- Control Segment or Panel – program the machine to various process specifications.

- Electric Panel and Electric Motors – It controls the electricity that powers the machine.

- Lubrication System – deliver oil or grease to all moving parts. This will avoid rust and excessive friction.

- Carton Tooling System – Defined the sizes and forms of the cartons. Carton tooling system cut and shape according to the requirements listed on the machine’s control panel.

- Ink-Jet Printers – conduct efficient carton printing to enhance identity.

- Safety System – comes with sensors for improved machine safety.

- Transport System – consists of conveyor systems, guide rails, and rollers. These move the product via various stations.

Why Choose JOCHAMP Blister Cartoning Machine

Jochamp is a reliable blister cartoning machine supplier. We have focused on cartoning machine manufacturing for more than 15 years. Through an advanced production system, skilled technicians and engineers support, we can develop automated machines that meet your budget and requirements.

Our range of blister cartoning machines has strong compatibility with suction box structure. It adapts to more specifications of cartons. The body of blister cartoning machines is covered with high-grade 304 stainless steel and has metal surface treatment. These offer stronger corrosion resistance and longer life. The machines are compliant with rigorous standards such as CE, SGS, ISO9001, and cGMP certification.

Our factory has thousands of stocks of standard blister cartoning machines. If you request a customized machine, we can manufacture it efficiently and can deliver in as fast as 15 days. When this machine is used as a production line, it provides a unique non-stop system and performance.

Key aspects must be considered while choosing a blister cartoning machine. The following are the most important variables to consider.

- Blister Cartoning Machine’s Safety

- Machine’s Production Capacity

- Amount of automation

- Additional Machining Tools

- Product to be packaged

As a professional blister cartooning machine manufacturer, we have the capability to customize your machine according to your specifications. You can provide the following details:

- Automation level

- Production speed

- Capacity for production

- Materials that should be used

- The machine’s dimensions

- The machine’s design, as well as other important details.

Custom Cartoning Machine Based on Your Applications

Ampoule Cartoning Machine is designed with movement mechanism protection and protective cover for efficient safety. This machine can be customized for the mechanical structure of different cartons. It has excellent quality and is offered at a competitive price.

Pharmaceutical Cartoning Machine is perfect for cartooning pills, swab, ointment tube, syringes, gloves, or other pharmaceutical products. It is designed from high-grade materials such as stainless steel. This machine can print product details in the carton making branding and marketing simple.

High-Speed Cartoning machines feature high efficiency, stable performance, high-capacity properties, etc. You can choose a specific model depending on your requirement. The speed of this series machine is up to 380cartons per minute. If you require a higher speed, we can customize the machine.

Jochamp manufacture horizontal cartoning machine with compact and reasonable structure. It makes a simple operation, convenient adjustment and higher degree of automation. Broadly used for packing the blister, pouches, bottles, sachets, and so on in cosmetic, pharmaceutical, food industries, etc.

Related Product

Blister Cartoning Machine: The Ultimate Guide

There are many blister cartoning machines in the market. Therefore, you should know the vital aspects of these cartoning machine such as features, design, working principle, and classification, criteria, amongst others. Keep reading.

A blister cartoning machine is a machine that automatically packages blister packs and is intended for use mainly in the pharmaceutical industry.

The machine can detect signal trouble, detect input overloads, and has self-adjusting feeding structures. These features ensure a fast and efficient cartoning process.

blister cartoning machine

The machine shapes and folds the carton into the desired shape, insert the product and seals the newly formed packaging. Blister cartoning machines are capable of other operations such as printing.

Although they are specialized blister cartoning machines, you can still use them to package other products like tablets, capsules, and food.

As said above, blister cartoners are specialized for blister cartoning. However, this doesn’t mean that they are exclusively for application only in that industry.

You can use blister cartoners in many other industries, e.g., cosmetics, to easily pack your products. You can package a few products: vials, sachets, capsules, bottles, medical tools such as scalpels, etc.

The following:-

- A blister cartoning machine ensures that your product is easy to identify—the machine prints product overview information on the carton.

- Blister cartoning is relatively cheaper in the long run compared to its alternatives.

You stand to enjoy additional benefits too, e.g., simplified marketing and branding because of its printing capability.

- The blister cartoning machine packages products and seals the package in a tamper-proof way.

This means it will be effortless to know if the packaging has been interfered with.

- Blister cartoning protects the products from physical damage and therefore plays a part in maintaining the product’s original composition.

Choosing the wrong machine for your process may result in lowered production efficiency in the long run, which might hurt business.

You must therefore choose a blister cartoning machine appropriate to your process requirements.

Comparing the following parameters against your production requirements should guide your selection process.

Product You Intend To Package

The blister cartoning machine cannot package just any product.

Be sure to research whether a blister cartoning machine is really what you require.

There are also different types of blister cartoning machines out in the market currently. Be sure to check if they can handle expected production capacities as well.

Requisite Automation Degree For Your Process.

There are two types of blister cartoning machines, i.e., semi-automatic and automatic.

Each has both advantages and disadvantages over the other. Weigh these pros and cons against your process requirements to see which is best.

Production Capacities

Be sure to select a cartoning machine that can keep up with the speeds and quantities that your process yields.

The following parts and components make up a blister cartoning unit:-

- The Control panel allows you to set the unit to specific production modes.

- Electric motors and panels supply and regulate the power that runs the unit.

- A lubrication system ensures all moving parts are not corroded or damaged due to friction.

They do so by channeling grease and oil to the necessary areas.

- Carton tooling apparatus. This part is crucial in designing carton shapes and carton sizes. It works on command from the control panel.

parts of a blister cartoning machine

- Printers to print out product details and specifications onto the carton in a sufficiently dexterous manner.

- Transport components consist of conveyer belts, guide rails, and rollers.

The blister cartoning machine inserts blisters into cartons in the following distinct stages.

- The first stage is the configuration of the unit to desired specifications.

Next, the machine draws the cartons from storage into its folding station for folding. The cooling system is the most crucial component of this process step. It folds the

cartons into desired sizes and shapes.

- The next stage involves sealing the carton sides. This ensures that they are strong enough to house components.

The unit applies different glue to this process depending on the carton type.

- The blister cartoning machine will then convey these newly formed cartons to the fitting station.

Here, the machine fits the blisters into the cartons and then seals them shut.

- The final step is printing.

The difference between both units arises from their operating speeds and the level of human oversight required. Semi-automatic blister cartoning machines are relatively slow compared to fully automatic units.

semi automatic blister cartoner machine

You will enjoy the following benefits with semi-automatic blister cartoning machines:-

i. Low maintenance costs.

ii. Easy configuration with safety devices such as HMI hence keeping it from damage.

iii. Customizable builds. You can incorporate additional units such as hot stamping and embossing machines, tape sealing, etc.

iv. They do not require highly specialized labor to operate.

v. Capability to produce batches in large, small, and medium-sized quantities.

automatic blister cartoner

The main difference between the two arises in how fast they operate.

Continuous motion blister cartoning machines are up to one hundred and fifty times faster.

continuous motion blister cartoner

This means that they are easier to handle.

Intermittent motion cartoners are, on the other hand, relatively slow.

This is attributed to the fact that they have more cartoning stages than continuous motion cartoners.

However, just because they are slow does not mean they are inefficient. In fact, it means the exact opposite.

Intermittent motion cartoners are best for packaging products with more complex features.

intermittent motion blister cartoner

A vertical blister cartoner machine packages the blisters by introducing them into the fitting station in a vertical manner.

It presents the following advantages over its horizontal counterpart:-

i. Ease in cleaning and maintenance.

ii. The working station is easy to access.

iii. It is customizable.

Horizontal blister cartoner machines employ the use of stack blanks. Rather than vertically introducing products, they make use of lateral drawers.

They are continuous motion and automatic hence very high-speed units.

This is an advantage.

The units can also automatically insert a specific number of products into the cartons, be it blisters, bottles, soft tubes, etc.

Their most important features are:-

- Integration of electronics, electrical & mechanical components, and air into its design.

- Operates only when vacuum and compressor air reach set points.

- They have a servo drive mechanism that monitors the loading system.

- Without input, there isn’t any suction.

There are two types of horizontal blister cartoning machines, i.e., auto or manual loading horizontal blister cartoning machines.

You can use online blister cartoning machines online by matching them to an interlink system. This will allow you to package the products from the production line automatically. You do not have to store the products for later packaging.

Offline blister cartoning machines will require manual actuation and package products right from storage.

Tamper-proof capabilities imply one thing and one thing only, product safety.

The tamper-proof sealing lets you quickly tell when the carton seal has been broken. This goes a long way in ensuring consumer safety.

Even though they are specialized blister cartoning machines, it doesn’t mean they are exclusively meant for application in the pharmaceutical industry.

You can use blister cartoners in chemical, cosmetic, nutraceutical, food industries, and many more.

You can use them to package bottles, vials, pastries, biscuits, etc.

The first and most crucial step to maintenance is troubleshooting.

- Shut down your unit as soon as you notice a problem.

Get the fault fixed and then run a performance test on the replaced or repaired part before resuming production.

- Ensure sufficient pneumatic pressure within the entire unit before starting production to enable smooth production.

- Replace old suckers with new ones frequently.

- Conduct an overhaul on the whole unit and then place the vacuum system in the correct position.

This will come in handy when you experience problems arising from mispositioned vacuums.

- Replace sucker tubing or unclog sucker tubes in the event of a blockage or air leakage.

- Use a servo system to facilitate smooth production in the case of poor stability of the unit.

This problem usually arises when you operate the unit at a very high speed for extended periods.

- Clean the machine frequently.

For all your blister cartoning machine needs, contact us now.