Biltong Packaging Machine Manufacturer in China

Jochamp is a reputable supplier that focuses on providing all kinds of biltong packaging machines that have high accuracy, high packaging speed, and ease of operation. We are highly capable of providing quality biltong packaging machines at competitive prices globally.

- More than 15 years of experience

- Offering customization services

- Certified by the, & ISO

- Provides lifetime after-sales service

Jochamp Biltong Packaging Machine

Jochamp offers a wide range of biltong packaging machines that can automatically finish the process of making bags, filling, packing, date printing, sealing, and many more. Our biltong packaging machines have a product contact surface that is made from corrosion-resistant stainless steel to guarantee the safety and hygiene of biltong products.

At Jochamp, our biltong packaging machines have a one-year warranty. We can also provide you guidance on how to operate, install, or maintain the biltong packaging machines. Life-time after-sales services are also offered at Jochamp.

For more information about our biltong packaging machines or services, do not hesitate to send us a message!

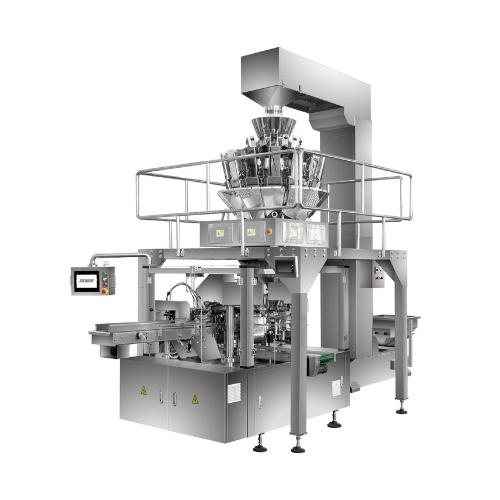

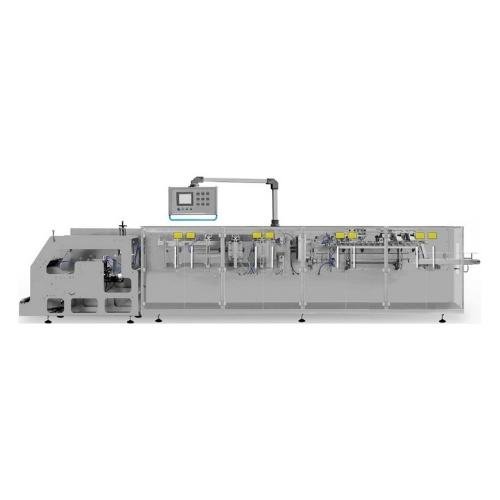

Rotary Packing Machine for Biltong

A type of bag-feeding machine. Named for its rotating packaging method. Compared with the horizontal bag-feeding machine, it is more friendly to large pouch.

- Compared with the horizontal prefab pouch packaging machine, the more compact design, less floor space

- One chuck and one bag, no bag shift phenomenon

- Compared with the horizontal prefab pouch packaging machine, it is more friendly to large bags

- IP55 waterproof grade, easy to clean

- The overall operating noise does not exceed 70 decibels (within one meter)

- Very powerful and friendly man-machine interface

JCR-200

- Technical Parameter

- Features

| Model :JCR | 200 | 350 | 150S | 330 |

| Bag-making size | L:100mm-300mm

W:70-200mm |

L:200mm-450mm

W:165-450mm |

L:100-300mm W:75-165mm | L:100-400mm W:180-330mm |

| Packing Speed | 20-50bags/min | 20-25bags/min | 60-90 bags/min | 5-40 bags/min |

| Filling range | 5-1500g | 5-4000g | 10-500g | 50-2500g |

| Filling precision | Error≤±1% | Error≤±1% | Error≤±1% | Error≤±1% |

| Packing material | Heat sealable film as PA/PE, PET/PE,Al film etc | |||

| Weighing method | Multi-head computer weigher, Auger filler, liquid filler, contraction cup, cup measure | |||

| Power Supply | AC 3P 380V 50/60HZ | |||

| Power | 3kw | 4kw | 3.8kw | 3.8kw |

| Machine dimension (L*W*H) | 1570*1440*1480 | 1800*1500*1800 | 2865*1645*2000 | 2150*1350*1750 |

| Mechanical weight | 1200KG | 1200KG | 3000KG | 3000KG |

- Compared with the horizontal prefab pouch packaging machine, the more compact design, less floor space

- One chuck and one bag, no bag shift phenomenon

- Compared with the horizontal prefab pouch packaging machine, it is more friendly to large bags

- IP55 waterproof grade, easy to clean

- The overall operating noise does not exceed 70 decibels (within one meter)

- Very powerful and friendly man-machine interface

- The whole machine is covered with 304 stainless steel, and the exposed metal parts are treated by electroplating, oxidation, etc., which is highly corrosion-resistant and has a longer life.

- 315 stainless steel, oxidized aluminum, PTFE and other food and drug grade products contact surface

- Passed CE, ISO9001, cGMP certification

- Optional electric gripper adjustment for faster size change

- Easy docking with rotary vacuum packaging machine

- Extensive packaging film support (multi-layer compound, Aluminum foil, laminating film, Paper laminating film etc.)

- Automatic circulating lubrication system

- Cold and hot two sealing systems to ensure 100% air tightness

- Suitable for different types of bags (flat pockets, stand-up pouches, spout bags, zipper bags, etc.)

- Optional 2-station model, double speed

- Open bag detection, no bag, no filling, no sealing

- Rich extended applications (date coding, discharge conveyor, easy tear hole punch, nitrogen flushing, etc.)

- Suitable for liquids, pastes, powders and granules through different automatic feeding mechanisms (multi-head scales, screw filling machines, elevators, etc.).

- Patented zipper bag opening device, higher opening rate

- Intelligent fault diagnosis

- Remote system diagnosis, maintenance and upgrade

- High hardness cam structure, longer life

- Using Mitsubishi, Siemens, Schneider, SMC, SICK, Omron and other internationally renowned brands of electrical appliances and accessories

- Humanized man-machine industrial control system, powerful and simple function operation

- Competitive prices

- Standard-level spot, customized machine can be delivered within 15 days at the earliest

Biltong Packaging Machine Features

Our biltong packaging machines come with a lot of features such as:

- Imported PLC & HMI system for stable operation and easy adjustment of parameters

- Adopt PID temperature control system

- Sophisticated sealing framework

- High weighing and packaging accuracy

- Consistent sealing & cutting

- Suitable for various kinds of packaging materials

- Advanced overload protection system for safety and to minimize failure loss

Options for the Biltong Packaging Machine

The biltong packaging machines can be added with optional accessories, devices, or machines depending on your requirements and applications. Some of the options include:

- labeling machine

- check weighers

- cartooning system

- other machines