Automatic Case Packer Manufacturer in China

JOCHAMP is a professional manufacturer of automatic case packers with automated case former, automatic case sealers, and an inserting system. We provide custom automatic packaging solutions to increase your business productivity.

- Offers high accuracy and precision

- Efficient packaging solution

- Compliant with safety standards

- Reduces packaging error

JOCHAMP Automatic Case Packer

JOCHAMP offers automatic case packers that are easy to operate, highly efficient and a reliable packaging solution. We designed each machine with superior flexibility to handle different product requirements. With our automatic case packers, rest assured that you can save labor costs while increasing efficiency and reducing human error. It can handle different applications such as high-speed packaging applications, low-speed packaging, or small foot-print packaging applications.

We offer high-quality solutions to different packaging needs for commodities, healthcare, medicines, cosmetics, and more. It serves different functions such as top-bottom sealing, product loading, and more. Here in JOCHAMP, you can purchase a wide range of fully automated case packers that will suit your requirements.

For your specifications, please contact us immediately!

Types of Automatic Case Packers

The Side Load Case Packer is a specialized packaging equipment that loads products into cartons by pushing them sideways. This loading method is particularly well-suited for square regular products, such as small cartons and square soap.

The side loading process efficiently positions square products inside the cartons, ensuring a snug fit and secure packaging. This method is especially beneficial for products with uniform shapes, as it allows for precise and consistent loading.

The Side Load Case Packer is widely used in various industries, from food and beverages to consumer goods and pharmaceuticals, where square or rectangular products are common. Its versatility and efficiency make it an essential asset for businesses seeking reliable and cost-effective carton packaging solutions.

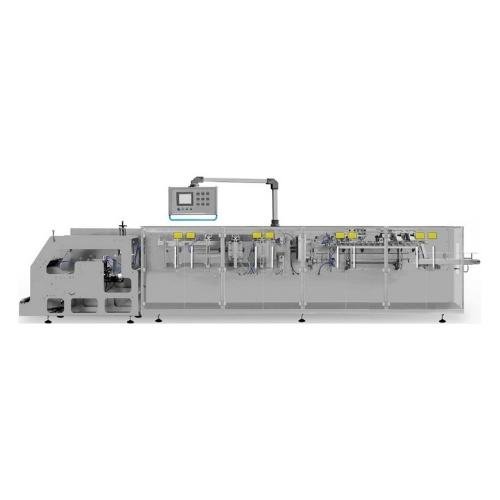

The Compact Case Packer is a highly efficient packaging equipment that combines the functions of unpacking, packing, and sealing within a single space. This integrated design optimizes the utilization of site space, making it a space-saving and practical solution for packaging operations.

By integrating multiple functions into one compact machine, it eliminates the need for separate equipment and reduces the overall footprint in the production area. This space-efficient design is particularly beneficial for facilities with limited space or those seeking to maximize their production floor.

The Compact Case Packer streamlines the packaging process, enhancing productivity and reducing manual handling. Its efficient operation ensures smooth and precise packing and sealing of products into cases, improving packaging efficiency and workflow.

This versatile and space-saving equipment is a valuable investment for businesses aiming to enhance their packaging operations while making the most effective use of their available site space.

The Wraparound Case Packer is an innovative packaging solution that utilizes a single piece of corrugated paper as the packaging material. This machine seamlessly integrates multiple functions, including corrugated box forming, feeding, and carton sealing.

Designed specifically for products that require wrapping, such as beverages, beer, and cans, the Wraparound Case Packer ensures secure and efficient packaging. Its ability to form the corrugated box around the products provides excellent protection during transportation and storage.

This advanced machine streamlines the packaging process, reducing manual labor and improving overall productivity. By using a single piece of corrugated paper, it optimizes material usage, minimizing waste, and reducing packaging costs.

The Wraparound Case Packer is a versatile and environmentally-friendly packaging solution, making it an ideal choice for industries that require wraparound packaging for their products. Its efficient and reliable operation ensures consistent and high-quality packaging, meeting the demands of modern packaging requirements.

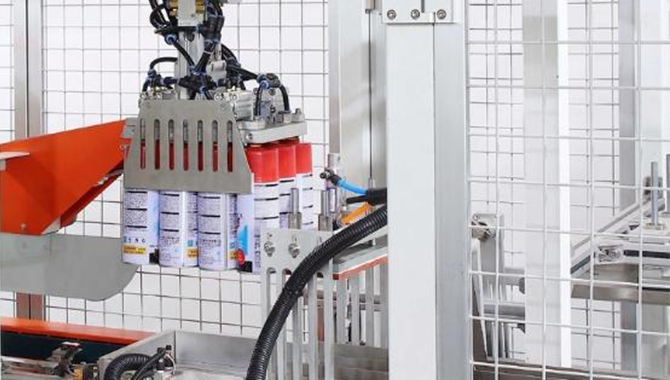

The Robot Case Packer is a highly versatile packaging equipment that incorporates a manipulator feeding system directly into the case packer. By utilizing a modified grabbing device, this machine becomes adaptable to a wide range of products.

The integration of a manipulator feeding system allows the Robot Case Packer to handle various product types and shapes with precision and efficiency. The grabbing device can be customized and adjusted to accommodate different product dimensions, ensuring a secure and precise placement into the cases.

This adaptability makes the Robot Case Packer an excellent choice for industries with diverse product lines, as it streamlines the packaging process for different items without the need for extensive reconfiguration or manual adjustments.

The innovative design and versatility of the Robot Case Packer contribute to improved packaging efficiency, reduced downtime, and enhanced overall productivity. Its capability to handle various products makes it a valuable asset for businesses seeking a flexible and automated packaging solution.

The Double Station Pick and Place Case Packer is an advanced packaging equipment designed for optimum space utilization and efficiency. It employs a straightforward servo-translational grabbing device to maximize the effective space during the packaging process.

The machine is equipped with two product feeding devices, allowing it to operate simultaneously on two production stations. This dual setup effectively doubles the packaging efficiency, reducing production time and increasing overall productivity.

With the servo-translational grabbing device, the Double Station Pick and Place Case Packer can precisely handle products and ensure accurate placement into the cases, optimizing the packaging process.

The combination of space-saving design and dual-station operation makes this equipment a valuable asset for industries seeking to enhance packaging efficiency and throughput. It enables businesses to streamline their production lines, improve workflow, and meet increasing packaging demands with ease.

The Case Packing Line offered by Jochamp Machinery is a fully customizable and tailored solution for packaging needs. With a focus on meeting customer requirements, Jochamp Machinery provides turnkey solutions, ensuring seamless integration and efficient operation.

The process starts with understanding the customer’s specific needs and site conditions. Jochamp Machinery conducts thorough planning and assessment to determine the most suitable equipment and layout for the packaging line.

Next, Jochamp Machinery matches the appropriate machines and components, ensuring they align perfectly with the customer’s desired output and production goals. This comprehensive approach guarantees that the Case Packing Line is optimized for efficiency and productivity.

Through their expertise and dedication, Jochamp Machinery delivers a complete and efficient packaging line, providing customers with a hassle-free experience and a fully functional packaging solution. With Jochamp Machinery’s turnkey solutions, businesses can focus on their operations, knowing that their packaging needs are in capable hands.

Why Choose JOCHAMP Automatic Case Packer

We manufacture an automatic case packer that offers maximum flexibility. It is also very versatile that it can be configured to meet different packaging specifications.

Our automatic case packers are manufactured with a simple and compact structure. These innovative machines are guaranteed to have low maintenance.

JOCHAMP automatic case packers have configurable speed. It can be set to 5 to 45 cases per minute to increase your industry’s packaging performance.

The automatic case packers are specifically designed to reduce human labor while increasing productivity. Therefore, you can save time, money, and chances of errors.

Fully Automated and Innovative Case Packers

Here in JOCHAMP, we manufacture a wide range of case packers that are fully automated. Each machine is innovatively and designed to meet every industry requirement. It can follow instructions to suit different box arrangements or shapes. Therefore, rest assured that it can pack vertical stacks, upright rows, square packaging, and more complex packaging needs.

By using an automatic case packer, incorrect packing numbers, foreign body introduction, and other related problems will be eliminated. It can certainly provide high accuracy even when used in a mass-produced product packaging. We can provide you automatic case packer that can provide up to 120 packaging per minute.

Working Process of an Automatic Case Packer

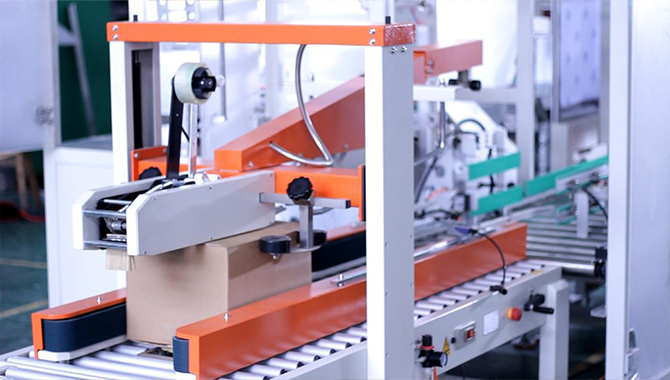

A part of the automatic case packer called vacuum cup places and opens the folded boxes into the forming position. Then the boxes are longitudinally transported through an angled arm and suction cup. The bottom flaps are fast closed through the machine. The products to be packed are grouped or positioned in a motorized roller conveyor belt for the product entry.

After that, the products are packed in a box vertically through the inserting system. Then, the lateral guides of the machine are responsible for case sealing by folding the flaps. The back flaps are also folded by the pneumatic system. Hence, the last step is bottom sealing the box.

Standard Technical Specifications

JOCHAMP manufactures high-quality and high performances automatic case packers with different standard technical specifications such as:

- PLC controlled

- 4kw installed power

- Manual size adjustment

- Touch screen LCD control panel

- Multifunction gripper

- 6bar air pressure

- Infeed motorized band

- Servomotors with up to 4 shafts for filling

One-Stop Solution for Your Packaging Requirements

JOCHAMP is a supplier of automatic case packers to provide a one-stop solution for your business or packaging needs. Our machines can help increase your industry’s productivity by providing accurate, efficient, and quick packaging. Each automatic case packer is equipped with sealers and case erectors to provide high performance. We offer different automatic case packers with custom specifications based on your needs.

It can provide a variety of functions such as drop-packing, side loading, top-loading, and more to meet your different packaging requirements. Here in JOCHAMP, we can help you find the right automatic case packer for your business.

Send us your inquiries today!

Our automatic case packers can accommodate different carton types with the following specification:

- 150mm up to 500mm in height

- 165mm up to 310mm in width

- 300mm up to 530mm in length

- FEFCO 0201, HSC, and RSC carton type

If you have specific carton dimensions, you can send them to us so we can manufacture an automatic case packer depending on your carton specifications.

We offer automatic case packers with complete and full accessories such as:

- Wheels with brakes

- Extensible conveyor connection

- Automatic input grouper

- Metal grid

- External protection

- Motorized warehouse

- Outfeed metal rollers, and more

You can also request a specific accessory from us!

Why Should You Use JOCHAMP Automatic Case Packer for Your Industry

We manufacture an automatic case packers with intelligent function while providing high-speed packaging. It can automatically alarm or stop the packaging process if a product is lacking. These are also integrated with a PLC touch screen control panel for easy and convenient use.

One of the advantages of our automatic case packer is its ability to pack different types of bottles. It can pack paper cans, square cans, glass bottles, irregular plastic bottles, oblate bottles, round bottles, and more. Our automatic case packer can also pack bottles in different sizes.

We manufacture an automatic case packer with a compact and simple layout yet supports different functions such as case closing, bag loading, case erecting, and more. It also offers high-quality case packaging at a high-speed rate.

Related Product

Automatic Case Packer: The Ultimate Guide

Choosing efficient and reliable automatic case packer can be an overwhelming task without the right information. A reason this guide explores all the vital aspects of automatic case packer machines. Keep reading to learn more.

An automatic case packer machine is fully automated equipment that has been programmed to run on its own.

You can use an automatic case packer to pack various products into cases or trays in readiness for shipping.

When working with an automatic case packer machine, manual labor is very minimal. The whole process does not require any physical assistance from the beginning to the end.

Automatic case packer

You can use an automatic case packer machine to pack a wide range of products.

This machine is used in many industries because of its many advantages.

The benefits of an automatic case packing machine include;

- An automatic case packing machine is high-speed.

This increases the production speed, which results in a lot of work.

This means the consumer can get their products in good time if an order is made.

- The machine reduces the overall production cost because of its production speed.

One can produce many products and get a lot of money for it.

Though it might be pretty expensive to purchase the machine, you will get back the money within a short time.

- An automatic case packing machine is relatively easy to use and maintain.

Its parts are not complicated, and the design is simple, making cleaning it very easy.

The maintenance of the machine is also straightforward.

- An automatic case packing machine is very effective and efficient and will give you value for your money.

It works very well, with little to no mishaps.

- An automatic case packing machine packages the products nicely, making it easier to transport the product.

It also makes it easier for a consumer to buy the product.

The products are packed very well, ensuring no damage or spillage if the products are in liquid form.

- An automatic case packing machine is very flexible.

This means you can pack many different products with different shapes and weights.

This benefits the packing company since you do not need several packing machines.

- An automatic case packing machine can save time, especially if the products are needed within a particular timeline.

The high production speed makes the packaging of the products very quick and effective.

- With an automatic case packing machine, materials are utilized well, and there is no wastage.

The machine has been configured to know the exact amount of material to use.

- An automatic case packing machine reduces labor costs since most machines do the work.

The machines also do not require supervision, and only minimal human labor is needed.

An automatic case packer machine is a very reliable and high-speed packing machine.

There are several kinds of automatic case packer machines.

They include a top load case packer and a side load case packer, among many others.

A lot of industries have benefited from using these machines.

Some of the industries include;

- The food and beverages industry – This industry uses different case packers like the drop load case packer to pack products such as bottles of milk, wine, and frozen food, among many others.

- Pharmaceutical industry – an automatic case packer is widely used in the pharmaceutical industry to pack products.

The industry uses different automatic case packers depending on the packed product.

- Automotive industry – since the automatic case packer machine is fast, it benefits the automotive industry.

They can pack a lot of products in a short time.

- Electronics industry – all electronics are very delicate are require a lot of care to avoid damage.

An automatic case packer machine comes in handy because using the machine will ensure the products are in good condition.

- Cosmetic industry – the cosmetic industry is one of the busiest industries worldwide.

An automatic case packer machine helps them keep up with the market demand since it is fast and reliable.

- Textile industry – the amount of production from textiles industries in a day is very high.

An automatic case packer machine is used because it can manage to pack all the textiles in a short time.

- Household products industry – household items are used in every house, so their demand is high.

With automatic packing, machine packing has made them more accessible than other machines.

- Hygiene products industry – an automatic case packer machine is used to pack products like hand sanitizers and hand wash.

Most of these products are delicate and hence require proper handling.

- The medical industry – is vital, and it benefits the most from an automatic case packer machine.

Its speed and effectiveness make it quite valuable for the industry.

- Chemical and petroleum industry – an automatic case packer machine is used in this industry because of its ability to pack products carefully.

Most products from this industry require gentle handling, which is possible with a case erector.

For any machine to work well, it needs some parts; without them, you will not be able to get the desired end product.

The list below contains the parts of an automatic case packer machine;

- Empty box dispenser – this is where the empty boxes are placed.

- Box erector is where the box is formed from a flat box and is folded and sealed.

- Conveyor belt – a conveyor is a belt-like structure where the products are placed and transported to where they are supposed to go.

- Staging area – this is where the products are placed before being released into a box or case.

- Box loader – the case is loaded with products into a box loader after assembling them according to how many will fit in the box.

- Case sealer – you can use case sealer equipment to seal a case or box after loading it.

- Vacuum blow-off – a vacuum blow-off is used to keep off the dust from the machine.

The working principle of an automatic case packer machine can be divided into three main groups; case erecting, case filing, and case sealing.

First step involves making a box or a case from a flat carton.

Case packer machine has a case erector that does the erecting of the box.

Additionally, the products are then loaded into a high-speed conveyor belt automatically.

Besides, the conveyor belt then moves the products to the staging area, where they are assembled.

Normally, the staging area is a tiny space with a bay door that lets the products into the staging area and then closes when the correct number of products is in.

They are automatically assembled in a prearranged sequence depending on how many the case can carry.

Next, the case is then moved automatically to the case filling station.

Automatic case packer machine has been programmed to know how many products are needed to fill one case.

The products are then dropped into the case. If the case allows another layer, it is added until its maximum capacity.

After the case is filed, it is moved to the case sealing station. This is where the sealing of the box is done.

There are several ways a case can be sealed, depending on the type of product in the case.

Finally, the machine then inspects the carton to ensure it has been sealed properly before moving it to the loading area where it is stored.

An automatic carton erector is fully automated to build a flat carton, shape the carton, and then fold and seal the bottom.

On the other hand, an automatic carton sealer is a machine programmed to fold and seal the flaps of a carton that had been erected already.

An automatic carton sealer can fold and seal the top and bottom of a carton, but with a case erector, only the bottom flaps are folded and sealed, leaving the top open.

An automatic carton sealer has four types, while a case erector has two types.

automatic case erectors

The parts of an automatic carton sealer are not the same as that of a carton erector.

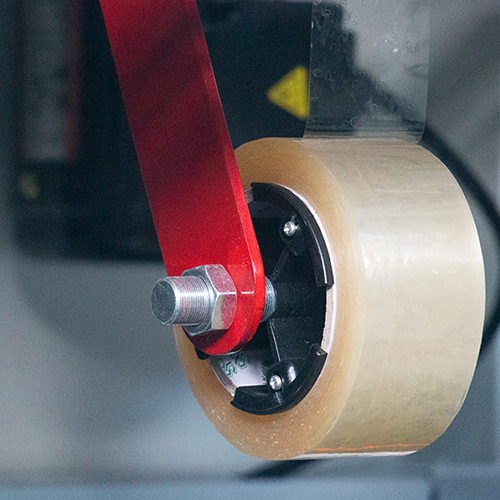

A case sealer has parts like a conveyor belt, taping mechanism, and tape holder, while a case erector has parts like shafts and taping wheels.

An automatic case sealer pushes the box onto the sealing station via the conveyor belt. This is where one set of holders holds it in place while another shaft lowers down to neatly tape the box’s top.

With a case erector, the flattened cardboard is pushed on the conveyor belt. This is where tong-like structures help to keep it straight.

case sealer

They shape it into a box and apply the adhesive tape to the bottom.

- Side load case packer – this case packer loads products into a case from the side of the case.

- Drop case packer – a drop case packer loads products into a case by dropping them from the top.

This type of case packer is almost similar to the top load case packer.

- Top load case packer – with a top load case, packer products are loaded into the case from the top.

You should use this case packer if you cannot load your products any other way.

- High-speed case packer – this is similar to the other case packers. The only difference is its packing speed.

- Bottom load case packing machine – with this equipment, products are loaded into the machine from the bottom of the case.

- Continuous motion case packer – a continuous motion case packer repeatedly runs until the whole production process is done.

- Intermittent motion case packer – this is suitable for productions that require multi-step packaging.

- Wrap-around case packer – with this equipment, you can place the product from either the side or the top of the wrap-around.

- Robotic case packer – robotic case packer is a case packer that has robotic technology to ensure effective and efficient product handling.

A semi-automatic case packer machine is an equipment that is not fully automated but has at least one automated function.

On the other hand, a fully automatic case packing machine is entirely automated, and all its functions are programmed.

A semi-automatic case packer requires manual assistance, and the operator or any person in charge does some of the work.

With a fully automatic case packing machine, little to no assistance is required since the machine can perform all the functions independently.

With a fully automatic case packing machine, the operator only needs to be set up before it starts running.

A semi-automatic case packer is relatively easy to install and set up compared to the fully automatic one.

semi automatic case packer

The fully automatic case packing machine is a bit complicated and requires a lot of time to be able to install and set up.

Regarding the cost of the two case packing machines, the semi-automatic case packer is cheaper than the fully automatic case packer.

This is because of its fully automated functions,

A semi-automatic machine is more flexible compared to a fully automatic case packer.

It can accommodate a wide range of box sizes and types. A fully automatic case packer allows for only one type and size per production.

With a semi-automatic case packer machine, the operator or the person in charge can easily make changes, do quality checks and even fix any problems without interrupting the whole process.

With a fully automatic case packer, once the machine starts, you cannot control it.

A semi-automatic case packer is slower compared to a fully automatic case packer.

The semi-automatic case packer is slower since it allows for adjustments when running, reducing the overall production speed.

automatic case packer

With a fully automatic case packing machine, you are assured of a high productivity rate compared to the semi-automatic one.

The fully automatic machine can produce a lot of products within a short time.

The production cost of a fully automatic case packing machine is cheaper since no manual labor is involved, and the whole process relies on the machine.

The features of any equipment are what make them desirable. The features you should look at first before getting any machine.

The features of an automatic case packing machine include;

- The case packing machine has a manual size adjustment

- It only requires little labor input. The machine does everything independently and requires little to no manual labor.

- PLC control

- Have bottom flaps sealing

- The machine comprises automatic feeding, filling, and sealing parts.

- It has an LCD-led touchscreen control panel

- The machine is made up of stainless steel frame

- The machine offers quick size changeovers

- High operating speeds

- User-friendly interface that is relatively easy to operate

An automatic case packer is automated equipment that you can use to pack your products into a case.

The significant difference between the two ways of packing is how the products are packed.

An automatic case packing machine loads products into a case, but with a tray packer, the products are loaded into a tray-like case.

Automatic case packing machine

The tray packer only loads one layer of the product compared to the automatic case packer, allowing for more than one layer.

Most products that rely on the tray packaging system need tight packaging.

Tight packaging is mainly done on fragile products or those that can be damaged easily.

The tray packer machine and the automatic case packer are made of heavy-duty material, making them very durable and long-lasting.

Both the automatic case packer and the tray packer are very versatile, and you can pack various products in different sizes and shapes.

An automatic case packer machine is faster than a tray packer machine.

tray packer

The automatic case packer and tray packer machine have very fast changeovers making the production rate very high.

The tray packer and the drop case packer are very effective and efficient when packing any kind of product.

For all your automatic case packer machine needs, contact us now.