It is important to invest in a high quality and reliable over wrapping machine in your packaging line. By the way, this is the first thing your customers see when they receive the goods. In general, efficiency and consistency are key elements of any ideal packaging. In other words, you have to make sure your products are wrapped with good elasticity to protect them in several ways and enhance their appearance.

But have you ever wondered what kind of equipment to use to package different products? Well, that’s what we want to discuss, there are many other factors in this guide. But first, let’s describe what this machine is.

1. What is over wrapping machine?

All right! This is actually a good question, especially when you hear it for the first time. For better understanding, I will make it as simple as possible. A wrapping machine essentially refers to packaging equipment that packs a product or group of products into a completely closed package.

Overwrapping machine

In most cases, the device is designed to cover the product by wrapping the flexible packaging material. It uses different types of materials, including a sheet of paper or film, etc., through a series of folding and sealing operations.

These materials tend to vary based on many factors, including paper, polypropylene, cellophane, and polyethylene, among others. This type of machine offers a high-quality level of performance, as well as producing a package with a nice feel.

Essentially, its flexibility and versatility make packaging an essential aspect of a wide range of industries. That’s it for a basic description of this particular device. As we dig deeper, we wanted to take a look at some common types ofover wrapping machines you might find in the market and across different industries.

2. Types of over wrapping machines

Well, we have several kinds of packaging equipment with different uses in different production plants. Of course, it is crucial to understand the various types of these machines so that you can easily understand which one is right for your needs.

For the most part, many people’s preferences depend on their specific packaging needs and resources. Nonetheless, let us find out some key types ofover wrapping machines;

1) Manual coating machine

This refers to physically operated or manually operated packaging equipment. When you use this type of foreskin machine, all you have to do is include all the necessary materials and then roll the handle accordingly. This is a best choice, especially for square and rectangular products such as soap, biscuits, etc.

Manual Overwrapping Machines

It is also suitable for the production of sample boxes and small quantity boxes, as well as fresh food packaging in supermarkets. Manualover wrapping machines are relatively easy to adjust and are therefore suitable for packaging products of various sizes.

So, if you are looking for a compactover wrapping machine for small packaging needs, then this should be your ultimate choice.

2) Semi-automatic over wrapping machine

As the name suggests, semi-automatic coaters are an improvement over manual coaters. Suitable for slightly higher packing rates. They are more expensive and more efficient than manualover wrapping machines.

Semi-automatic overwrapping machine

For short batch packaging, semi-automatic coaters can be relied on. Unlike manual over wrapping machines, some operations of semi-automatic over wrapping machines are fully automatic. Of course, some operations require a technician.

For example, most semi-automatic coaters are able to fold and seal automatically, with an operator monitoring the operation through a control panel. It also has a machine operator’s station to perform some operations that the machine cannot handle automatically.

3) Fully automatic over wrapping machine

For high volume and fast packaging, you can rely on fully automatic coaters. Fully automatic foreskin machine for all foreskin applications without manual intervention.

Fully automatic over wrapping machine

As you can see, the fully automatic coater has a robust control system. All operations are coordinated by the PLC control system, such as:

- Feed film packaging

- feed the item you want to pack

- heating film

- cut movie

- Packaging items, among other things.

Ideally, it provides a seamless packaging solution you can rely on. In conclusion, whether to choose a manual coater, a semi-automatic coater or a fully automatic coater depends on your packaging needs.

3. Why do you need an over wrapping machine

Let’s get straight to the point; This device is necessary if you need your product to have an appealing look upon entering the market. Investing in this equipment is crucial as it allows you to easily benefit in a wide range of ways. Some of these methods include:

1) Improve inventory control

You see, inventory control is easier when you stack similar products together. In a busy production facility, you at least want to go through the messy and time-wasting inventory counts.

Ideally, a packaging system can bring safety and consistency to your production line, no matter its size and warehouse location. So in other words, this practice makes it easy for you to enhance your inventory control needs whenever you need it.

2) Improve speed and efficiency

You can never compare the speed and efficiency of packaging products by hand and by machine. This is unparalleled! The thing is, this machine can easily increase the packing rate in an efficient way. In an ideal world, this is necessary because it gives you an edge in the market to capitalize on customer needs in a way.

3) Reduce labor requirements

You see, the essence of using any machine in this situation is to help reduce labor requirements. The unique features of theover wrapping machine allow you to achieve the best results in the shortest time. So you don’t necessarily need manpower as these machines are integrated to perform different tasks related to packaging.

4) Low risk of injury and accident

Using a packer will keep you or your operator safe 99% of the time. I would say that while you are using this machine, there is less chance of injury from accidents related to its operation. The fact that there is little interaction between the over wrapping machine and the operator, especially the automatic over wrapping machine, also adds to its safety.

5) Reduce operating costs

The ultimate benefit of using an over wrapping machine is that it allows you to cut a lot of operating costs. In business, the essence is to always make sure that you maximize your profit margin while always delivering a high-quality service or product.

So, if there is a way that can be used to achieve this ultimate commercial goal, by automating most of the line operations, including packaging.

6) Protect your cargo from dust, moisture and damage

If there’s one key benefit to a packer that you can easily take home, it’s this one. Listen, once you’ve finished producing the products, the next thing is to get them into the market for consumption. However, keep in mind that market dynamics are quite numerous and they tend to influence consumers’ purchasing decisions in several ways.

First, the ideal packaging is what makes the product attractive. The reason you need to invest in this machine is that it enhances the overall look of the item. Second, it makes it easier for products to have a longer shelf life. I mean, packaging protects your items from dust, moisture, and unnecessary damage.

So at the end of the day, you’ll improve the quality of the product while extending its shelf life.

As you can see, it is clear that the investment in this machine is quite worthwhile. Your investments tend to gain value in several ways. Next, I want us to look at some basic factors to consider when you choose to buy an over wrapping machine.

4. Main parts of coating machine

Well, getting a wrapping machine can be quite an investment, so make sure you take care of it properly. In most cases, you will need to replace the many frequently worn parts of this machine. So, if you want to extend the life of your machine, you should know the right time and parts to replace frequently.

Parts of the over wrapping machine

Of course, as a unit, it’s made up of several parts and components, and obviously, we can’t discuss them all here. In this case, I will only touch on a few but critical parts of the machine that you must understand, as a way to increase efficiency.

1) PLC screen

This is the component that issues all commands and controls. Some models have a touchscreen interface, which makes it easy to control the machine by simply pressing the correct key. This is a vital component as you also use it to monitor various parameters of the machine including speed adjustments etc.

2) Motor

This refers to electronic components that convert electrical energy into mechanical energy. The capacity of each motor in these devices depends on the size of the machine. But ideally, it is a necessary component to improve machine reliability, especially during longer operating hours.

3) Magazine

Refers to the component used to stack products that require labeling. The magazines come in different sizes, which means they line up packing with different capacities of such products.

4) Temperature Controller

This is a device used to control this instrument without your involvement as an operator. This is a necessary component because it enables you to decide how to adjust the temperature of the machine as needed. This way in the end, you can find the right temperature for the best results at all times.

5) Heat sealing machine

It refers to a part of the over wrapping machine, which is mainly used for heat-sealing packaging of products. Thus, these components essentially enable the wrapping material to cover the item tightly and attractively. Some instruments come with stationary heat sealers, while others come with portable ones.

5. How the over wrapping machine works

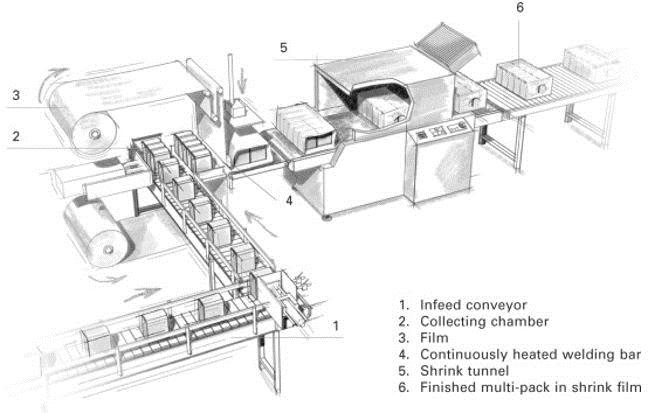

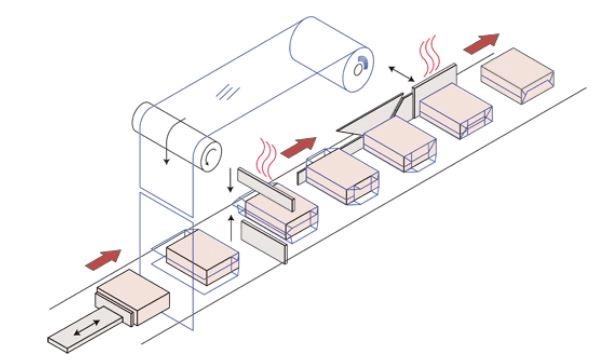

It is crucial to understand what the different aspects of an over wrapping machine are that make it work effectively. Knowing how the device works is also a fundamental idea, especially for efficiency and best results. But before we get into how it works, let’s first know that this machine has three key functions; Primary, secondary and transit foreskin.

Over wrapping machine process

Ideally, the material of the primary packaging contrasts with the product, such as a loose box of playing cards. Secondary packaging means that the product has already been packaged in a different style, this time you need to add an outer packaging on it.

This is followed by transshipment packaging, which is mainly used for the finishing of loose products. Knowing these features can give you an idea of how this machine works. Speaking of how it works, the principle is that the product is pushed through from a single real film sheet.

What happens is that where the films tend to overlap, either the longitudinal heat seal or the substrate heat seal. This device mainly consists of different mechanisms. It has a packaging mechanism, a transport unit for receiving, moving and unloading items. It also contains a roll of packaging material, ready to label, a gluing device, and in some cases a counting device.

How it works for over wrapping machine

Therefore, the items are either packed on a turntable or in a line, depending on the configuration of the over wrapping machine. Such packaging is characterized by periodic transfers from one operating member of the packaging mechanism to another such member.

This allows for one-, two- or three-layer packaging. For the most part, how this machine works, as you can see, it’s pretty simple, all you need to do is make sure you integrate the appropriate parameters. What’s more, the machine can be used both as a stand-alone unit and as an automatic pre-packing and packaging equipment.

6. Precautions when buying an over wrapping machine

The truth is, there are several things you need to consider before you consider buying a suitable over wrapping machine. The reason I say this is that investing blindly in these devices can be a costly mistake. So no matter the size of your company or your production needs, you have to make sure you have at least some elements in mind.

In this section, I’ll briefly discuss some of these key elements with you to give you an idea of what’s going to be and what’s going to be done.

1) Availability

When considering purchasing this machine, you should always make sure that it is easy to handle. Well, you could argue that most of them are automated, so it’s just a matter of pressing a control button. This may just be a fallacy! All you need to do is make sure you know how to operate the machine.

2) Technology

This is also another undoubted element that you should never forget to consider when purchasing this machine. Considering that much of the operation of this equipment is automated, it is prudent to choose equipment with a high level of technological integration.

3) Flexibility

A suitable foreskin machine should be flexible anyway. It just means that you should be able to pack a variety of different sized items with minimal conversion. In this way, you can guarantee the necessary efficiency and reliability when packaging various products at the same time.

4) Exterior

This is what happened; Many people pay little attention to the design features when purchasing an outer packaging device. Well, sometimes, it’s unnecessary, especially when you’re sure its performance and other related aspects are top-notch.

5) Size

Of course, the size of the machine is another fundamental factor you must consider when purchasing. In most cases, relatively large equipment is always suitable for mass production, mainly for factories. However, if your production is on a smaller scale, choosing a smaller unit is feasible as long as it can serve you efficiently.

6) Material construction

So, when you’re out shopping for over wrapping machines, you’ll notice that most manufacturers use or use different materials. Of course, you have to consider the environment and many other factors, including the type of product you’re packaging.

7) Cost

You have to agree with me, even a quick search online now will reveal different prices for this machine. Of course, there are several factors that guide a particular price tag for a particular type of over wrapping machine. Still, the bottom line is that you need to buy an over wrapping machine that is good value for money.

8) Conversion

Of course, this usually happens when there are differences in packaged products. This also occurs when elements of different types need to be merged during the wrapping process. Therefore, you should make sure that the machine you buy allows for as few replacements as possible.

9) Package rate

Well, the truth is, the essence of using a foreskin is to increase speed and reduce wasted time. Therefore, it is prudent to choose a machine with a reasonable pack rate per minute or hour. In this way, you can pack a large quantity of goods that need to be delivered to the market in the shortest possible time.

10) Maintain

You see, when you buy this kind of equipment, you also need to take into account its maintenance needs. For example, you need to calculate the cost availability of spare parts. You also need to determine how easy it is to repair parts, and how often to make general repairs.

11) Mode of Operation

It is necessary to decide your choice based on how the machine operates. It will let you know how to use it. Most of the coating equipment has two main modes of operation, including:

- Mechanical

This, you basically need to do most of the operations manually.

- Servo

This is a mechanism that uses error-induction negative feedback to correct various actions of the machine and automate different parameters of the machine.

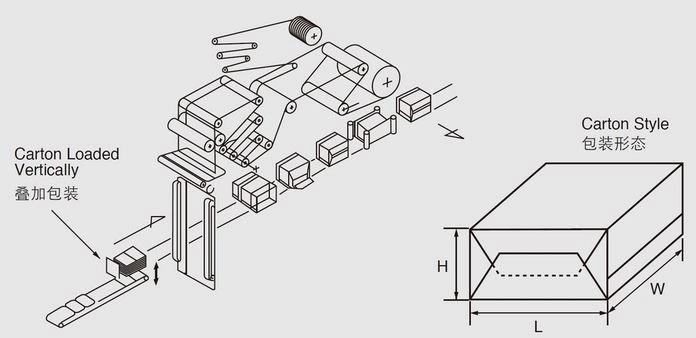

12) Packaging style

The type of packaging used by the machine you choose is also an important factor you should consider. Different models have different packaging styles. However, the main styles include the following;

- Hug under wrap

- 2.Cello packaging

So, depending on your preference, you may choose the right packaging style for you. Alternatively, you can opt for a wrapping machine that offers a wide range of wrapping styles. So, first of all, all these points that I briefly describe here are very necessary whenever you buy this kind of equipment.

They increase the chances of getting a highly reliable and efficient process, making it easier for you to achieve the desired results. In the next section, I want us to also look at an equally important aspect of the over wrapping machine;

7. Use requirements specification.

Packaging machine user requirements specifications URS, as it is generally considered to be one of the strict regulations that all machinery manufacturers have to comply with. The essence of URS is to ensure that all specified quality standards are maintained with regard to machine operation. Therefore, when purchasing this instrument, you will get a URS document, which is ideally mandatory. For this reason, let’s now take a look at some of the details you can find in this particular document.

1) Approve

This section forms one of the foundations of the document, as it identifies some person or agency involved in reviewing and authorizing the use of this device. All approvers must sign to authorize use of the machine.

2) Introduce

This section provides you with highlights about many elements of the device. In this section, you’ll see the general description, design, operational details, and more.

3) Outline

As far as the operation of this machine is concerned, the outline section requires some form of detail. Some of the aspects described in this section include the required production rate, the number of package sizes involved, the frequency of changes and labor requirements, etc.

4) Product demand

The focus of this section is to understand the various factors surrounding the process and design specifications. Examples of some elements in this section of the URS include packing rates, operating systems, and general maintenance and machinery sections.

5) Safe question

This section details the machine and operator safety perspective.

6) Compatibility

It highlights all other devices and accessories that are compatible with this unit and work effectively with it.

7) Acceptance Test

8) Supply demand

It discusses some of the key factors that manufacturers care about in providing instruments to their customers.

9) Limit

10) Quality Standard

11) Abbreviation

This section describes all short forms and codes used in this document. When you read the URS, you will notice that several of the words are either encoded or abbreviated. To better understand these terms, the abbreviations section will give you an idea.

8. Application of over wrapping machine

Now, as we approach the final part of this guide, I still need us to discuss this important element. By any standard, understanding the common applications of such machines is crucial. This will give you a practical understanding of what it does and how it works.

Packaging machine application

No doubt, on one or more occasions, you have come across the application of these tools, whether intentional or not. To this end, let me briefly introduce some common applications of over wrapping machines.

1) Pharmaceutical Industry

This instrument is widely used by most of the pharmaceutical industry. By the way, it is one of the assembly line equipment necessary to package the product before the product is finally on the market. So, when you take a walk in any of the comprehensive pharmaceuticals, you will find that this type of machine is widely used in the manufacturing process.

2) Food processing

This is another area where the use of such equipment is common. Often, you’ll see a variety of food items in nicely packaged containers. In most cases, food processing companies use this machine because it helps ensure that the packaging meets the required standards. It also helps ensure that the packaging is attractive to guarantee laudable sales from consumers.

3) Chemical

Most chemical manufacturing companies also use this type of machine to seal their products.

As you know, most chemicals are always considered harmful, so make sure they are well packaged. This makes it easy to protect humans, animals and the environment as a whole from chemicals.

4) Industrial package

Well, the truth is that a lot of the industrial products you need are often packaged for a variety of reasons. As we discussed earlier, this packaging has many benefits for the product.

Increased shelf life, attractiveness, damage prevention, and more are just a few of the reasons. In fact, such machines are used by some industries that need to package their products accordingly.

9. In conclusion

Well, by now, you should have noticed that the over wrapping machine is actually quite an important addition to the assembly line. This guide also reveals to you a lot of details about this instrument that you may not know.

Still, the bottom line of this article is that with so many coverage tools, it certainly matters. So the next time you want to own a car, just use this article as your reference point and you’ll be on your way.

Now, do you have any news? Do you have any suggestions, comments, enquiries or anything to add? Please leave a message in the comment area. We will contact you again!

[read_meter]

Other Related Information:

For all your carton folding machine needs, contact us now.